Phase

1: Concept design

Competitive Product Research and Concept Brainstorming

From the start, the overall project goal and product design specifications are defined, followed by a detailed market analysis. The documented competitive and related product internet and in-store research is then analyzed to identify product development strategies. The market research is revisited throughout the new product design and development phases.

Deliverables include project planning, competitive product analysis and market research. Product design exploration is the second objective of this phase. Our product designers sketch during research and the kick-off meeting as ideas and concepts are verbally contributed. Design refinements to the concept sketches made after the client's initial review.

⇣

Preliminary Ergonomic Design

In order to develop a user-centered design, human factor studies are conducted to perfect the comfort level of the end-user. Textbook data, from Humanscale 1/2/3, is compared to real life data and anthropometric research. Further ergonomic analysis is performed by testing a mock-up model to gather observational research and tactile feedback. All research is factored into concept development to create the most user-friendly designs possible. Deliverables include ergonomic diagrams, digital images and conclusions based on our findings.

⇣

Concept Renderings

The assessment of the product research and concept brainstorming narrows down the new product design to a few chosen concepts. The final selections are illustrated as 3D Color Renderings using SolidWorks, PhotoShop and Keyshot software. The Computer Aided Design (CAD) provides a window to the future appearance of the new product. A color study may also be explored at this time. The concept renderings help evaluate the aesthetic design options before extensive time and resources are expended. Deliverables include color concept renderings and aesthetic design evaluation.

⇣

Phase 2: Prototype design

Solidworks CAD Geometry

The new product design is created as 3D Prototype Geometry completed in SolidWorks design software. Prototype design contains fully defined exterior surfaces with draft, preliminary ribs, bosses and parting line joints. The prototype geometry is built around interior components with clearance checks performed based on client specifications. The prototype geometry is a valuable template for the final design, however it is not used directly for production tooling. Deliverables of Phase Two include the prototype geometry and preliminary product graphics.

⇣

Refined Industrial Design + Graphic Design / GUI

After a round one concept is selected, feedback from client, engineering, and manufacturing is factored into the design and construction. The concept is further refined to achieve the best, most appropriate aesthetic form and functions given the desired materials, manufacturing methods, and finishes agreed on by all invested parties. The updated design is rendered to a high level of detail to provide a photorealistic preview of the finished product. Graphic design and Graphic User Interface (GUI) is necessary to develop a user-friendly product. This design effort includes both 2D Graphic Design and 3D Interactive Analysis. Projects include logo and icon design, as well as instructional and interactive graphics. Graphic design refinements are made throughout the new product design and development phases. Deliverables include product graphics, traditional button, membrane, and capacitive-touch control panel graphic layouts, as well as LCD touchscreen interactive designs.

⇣

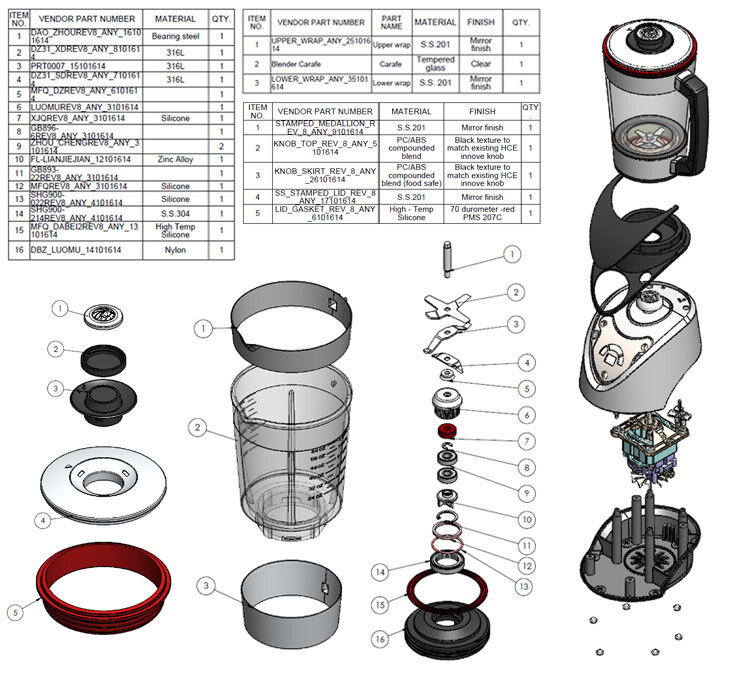

Prototype B.O.M.

A Bill of Materials is created from the Solidworks prototype geometry. This is an integral document that communicates all of the information about the actual physical construction of the product, such as: part names and descriptions, the potential part manufacturer, material, finish, potential production processes, and quantity. This information always accompanies an exploded view of any assemblies to visually show how the parts are assembled. The B.O.M. is shared with management, engineering, and manufacturing to ensure all relevant parties have a full understanding of the product design.

⇣

Phase 3: Prototype build

A prototype model is built using the prototype geometry to physically represent the new product design. The aesthetics, number of parts, service, industry standards, potential manufacturing processes, materials and assembly are all represented as accurately as SLA, CNC, and 3D Printing processes permit.

We can provide silicone rubber molds and multiple cast parts with threaded brass inserts when several prototypes are required. Painted steel, machined aluminum, and stainless steel prototype parts are also available. Deliverables include a functional prototype model and prototype evaluation.